Types of Diamond Blades

– Circular diamond saw blades

– Diamond gang saw blade

– Diamond band saw blade

– Diamond blades designed for specific uses (marble, granite, concrete, asphalt, masonry, gem-cutting)

– General purpose blades

– Continuous Rim Blades

– Segmented Blades

– Turbo Blades

– Dry Cutting Blades

– Wet Cutting Blades

Manufacturing Methods

– Electroplating

– Vacuum brazing

– Sintering

– Wholly sintered diamond blades

– Silver brazed and laser welded diamond blades

Application of Sintered Metal-Bonded Diamond Blades

– Diamond blades grind through material

– Bond controls the rate of diamond wear

– Bond needs to match the specific material being cut

– Factors to consider: type of blade, availability of water, horsepower of the saw, acceptable level of noise

Cutting with or without Water

– Blades designed for wet or dry cutting

– Diamond tools and blades work better when wet

– Water prevents overheating and reduces harmful dust

– Dry cutting should be limited and cooling measures should be taken

– OSHA regulations for silica dust in dry cutting

Maintenance, Safety, and OSHA Regulations

– Factors to consider when choosing diamond blades

– Maintenance and safety tips for diamond blades

– OSHA regulations and silica dust exposure

– Importance of proper storage and handling of diamond blades

– Employer responsibilities and worker training for silica dust control Source: https://en.wikipedia.org/wiki/Diamond_blade

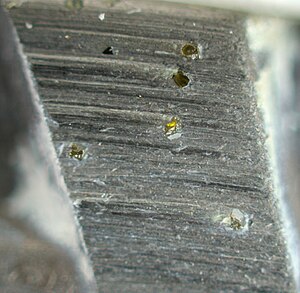

A diamond blade is a saw blade which has diamonds fixed on its edge for cutting hard or abrasive materials. There are many types of diamond blade, and they have many uses, including cutting stone, concrete, asphalt, bricks, coal balls, glass, and ceramics in the construction industry; cutting semiconductor materials in the semiconductor industry; and cutting gemstones, including diamonds, in the gem industry.