Introduction to Computer-Aided Manufacturing (CAM)

– CAM is the use of software to control machine tools in the manufacturing process.

– It can assist in all operations of a manufacturing plant, including planning, management, transportation, and storage.

– CAM aims to create a faster production process with more precise dimensions and material consistency.

– It helps minimize waste by using only the required amount of raw material.

– CAM is now used in schools and lower educational purposes.

CAM in Relation to CAD and CAE

– CAM is a subsequent process after computer-aided design (CAD) and sometimes computer-aided engineering (CAE).

– CAD models can be input into CAM software to control the machine tool.

– CAM is commonly used in schools alongside CAD to create objects.

History and Challenges of CAM

– Early commercial applications of CAM were in the automotive and aerospace industries.

– CAM software had shortcomings that required manual editing by skilled CNC machinists.

– CAM software would output code for the least capable machine, limiting flexibility.

– Improperly set up CAM software or specific tools required manual editing for proper program execution.

– CAM packages could not reason like a machinist, leading to suboptimal toolpaths for mass production.

– Mass-produced items often required casting or non-machine methods instead of CAM.

– There is a shortage of young, skilled machinists entering the workforce.

– CAM providers are addressing historical shortcomings through niche and high-end solutions.

Overcoming Historical Shortcomings

– Out-of-the-box capabilities, process wizards, and templates improve ease of use for new CAM users.

– Integration with 3D CAD environments enhances user confidence through visualization and simulations.

– CAM systems now support a wide range of machine tools, including turning, 5-axis machining, and laser cutting.

– Integration with PLM and the extended enterprise streamlines manufacturing and supports the full needs of manufacturing personnel.

Related Concepts and Technologies

– Computer-integrated manufacturing (CIM) is related to computer-aided manufacturing.

– Digital modeling and fabrication are important in the manufacturing process.

– Direct numerical control (DNC) is another aspect of computer-aided manufacturing.

– Flexible manufacturing systems (FMS) are used in modern manufacturing processes.

– Integrated computer-aided manufacturing (ICAM) is an important concept in manufacturing process management (MPM).

– G-code is a programming language used to control CNC machines.

– Numerical Control (NC and CNC) machines revolutionized the manufacturing industry.

– Robotics in manufacturing automate repetitive tasks, increasing productivity. Source: https://en.wikipedia.org/wiki/Computer-aided_manufacturing

This article needs additional citations for verification. (October 2009) |

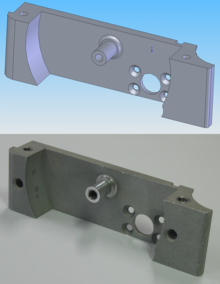

Computer-aided manufacturing (CAM) also known as computer-aided modeling or computer-aided machining is the use of software to control machine tools in the manufacturing of work pieces. This is not the only definition for CAM, but it is the most common. It may also refer to the use of a computer to assist in all operations of a manufacturing plant, including planning, management, transportation and storage. Its primary purpose is to create a faster production process and components and tooling with more precise dimensions and material consistency, which in some cases, uses only the required amount of raw material (thus minimizing waste), while simultaneously reducing energy consumption.[citation needed] CAM is now a system used in schools and lower educational purposes.[where?] CAM is a subsequent computer-aided process after computer-aided design (CAD) and sometimes computer-aided engineering (CAE), as the model generated in CAD and verified in CAE can be input into CAM software, which then controls the machine tool. CAM is used in many schools alongside CAD to create objects.